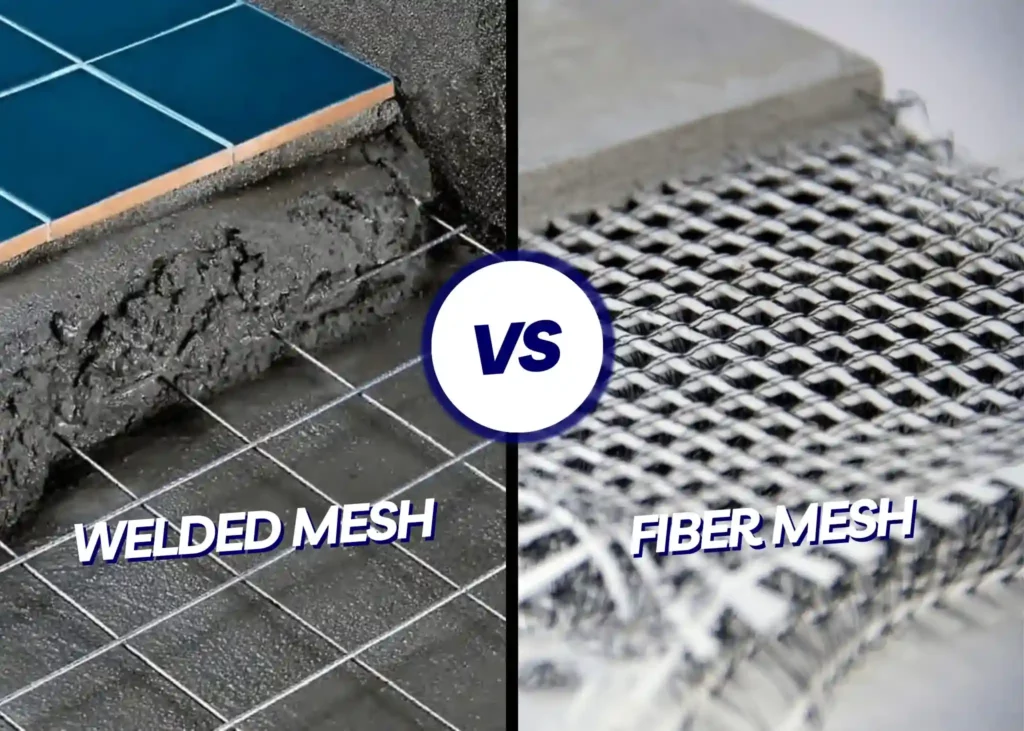

When it comes to reinforcing concrete, There is still a debate on “Is Fiber Mesh Better Than Wire Mesh” or not. Both of these materials serve the essential purpose of enhancing the strength and durability of concrete structures. In this article, we will delve into the world of pros and cons of fiber mesh vs wire mesh, exploring their pros and cons to help you make an informed decision regarding which one to use for your specific project.

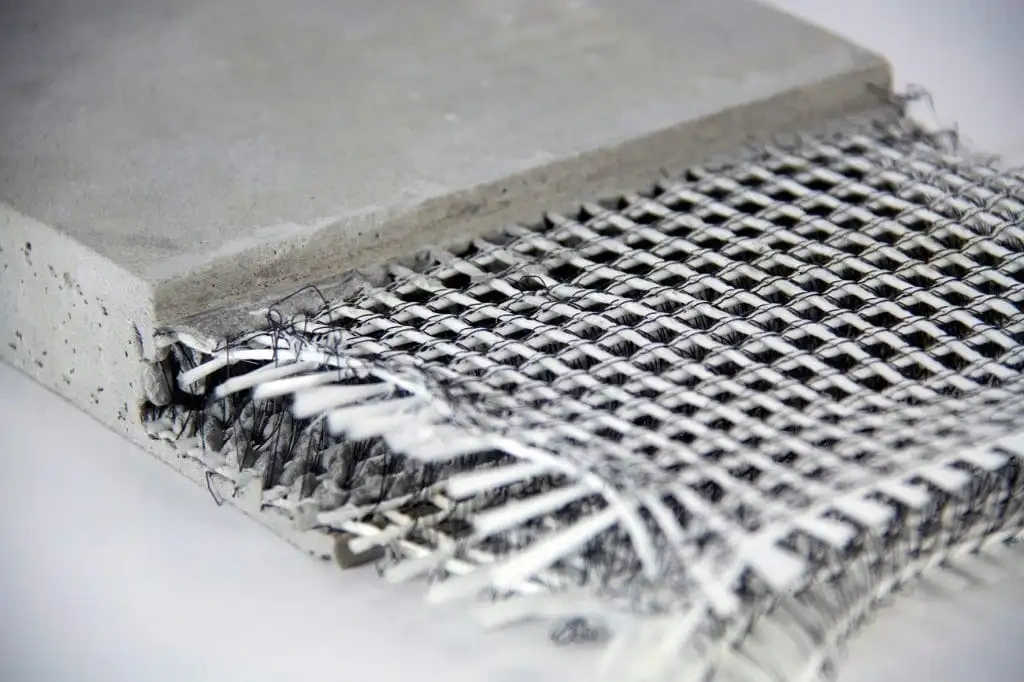

Understanding Fiber Mesh

Fiber mesh, also known as synthetic fiber reinforcement, is a relatively modern addition to the construction industry. It involves adding tiny, discrete fibers made of materials like glass, synthetic polymers, or steel to the concrete mix. These fibers create a three-dimensional support network within the concrete, improving its tensile and flexural strength.

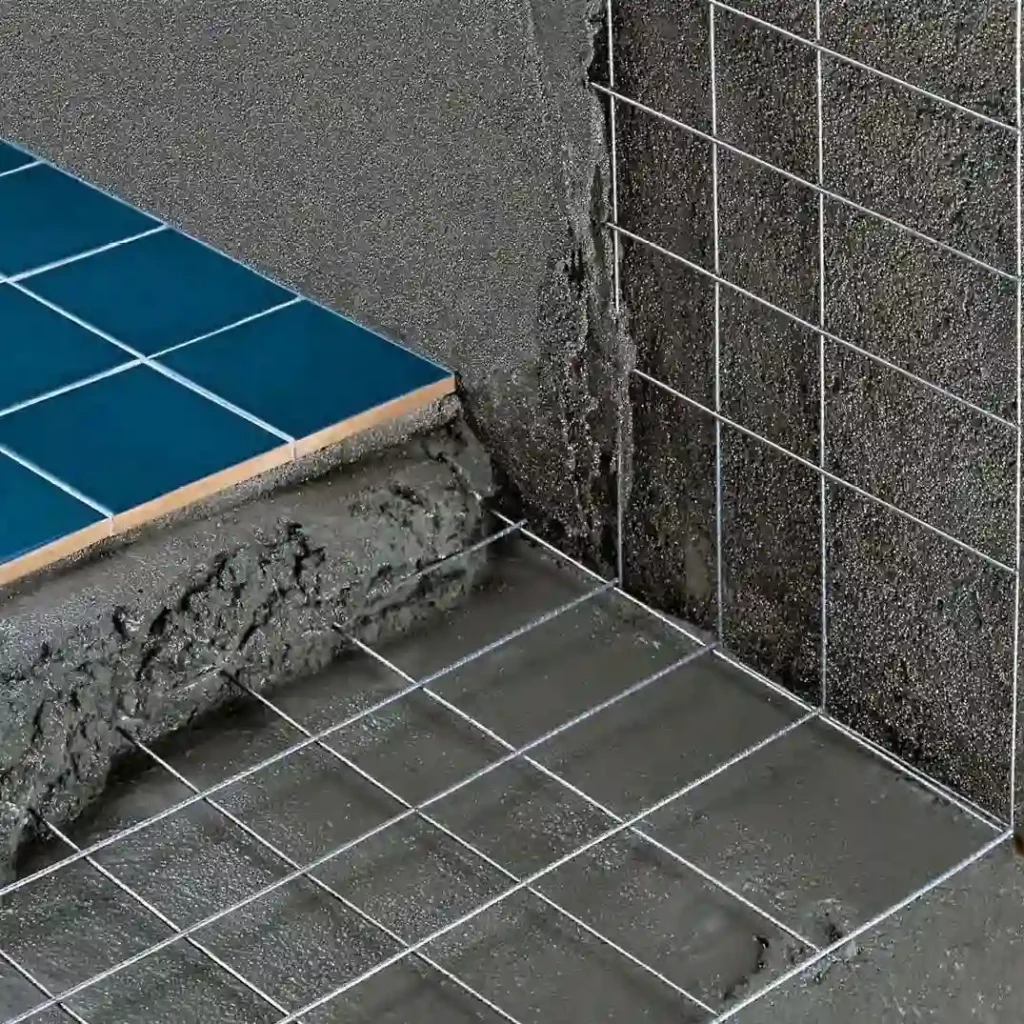

The Versatility of Wire Mesh

Wire mesh, on the other hand, is a more traditional choice for concrete reinforcement. It consists of sheets or rolls of welded or woven wires that are laid out within the concrete. Wire mesh provides structural support by distributing loads evenly and preventing cracking.

Fiber mesh vs wire mesh

Strength and Durability

Wire Mesh

Wire mesh is known for its strength and ability to reinforce concrete effectively. It prevents cracks from widening and provides support against structural stresses.

Fiber Mesh

Fiber mesh enhances the durability of concrete by reducing the risk of cracking. It disperses stress throughout the structure and mitigates the formation of shrinkage cracks. It is particularly useful in controlling cracking due to plastic settlement.

Is fiber mesh better than wire mesh in terms of Installation and Cost-effectiveness?

Wire Mesh

Wire mesh installation is much easier and less labour intensive. It involves placing out the mesh manually, which can be which can be done quicker than installing fiber mesh. The cost of labor and the equipment needed for installation can make it a more expensive choice.

Fiber Mesh

Installing fiber mesh is a straightforward process. It is often pre-blended with the concrete mix, reducing labor costs and making it a cost-effective option in terms of installation. It requires minimal equipment and is easy to handle.

Fiber mesh vs wire mesh on Resisting Environmental Factors

Wire Mesh

YKM Wire mesh, being made of SS316 steel prevents corrosion when exposed to moisture and chemicals and can last longer period.

Fiber Mesh

Fiber mesh is resistant to corrosion and rust, making it a suitable option for applications where exposure to moisture or chemicals is a concern. It can withstand harsh weather conditions and is ideal for outdoor projects.

Aesthetic Considerations

Wire Mesh

Wire mesh remains visible within the concrete, which can provide a aesthtic appearance to the finished product. It can be the best choice for projects where looking for an aesthetic appeal.

Fiber Mesh

Fiber mesh is virtually invisible once the concrete is cured. This makes it an excellent choice for projects where visibilty of the mesh is not preffered.

Is Fiber Mesh Better Than Wire Mesh in terms of Handling and Transportation

Wire Mesh

Wire mesh, being made of steel, is heavier, which can complicate handling and transportation upto some extent.

Fiber Mesh

Fiber mesh is lightweight and easy to transport. Its integration into the concrete mix simplifies the handling process, making it convenient for contractors.

Comparing Performance in Concrete

When it comes to concrete reinforcement, fiber mesh and wire mesh exhibit differences in performance. Fiber mesh is excellent at controlling cracking, especially in scenarios where shrinkage cracks are a concern. Wire mesh, on the other hand, excels in offering structural strength and preventing cracks from widening.

Weight and Load-Bearing Capacity

Fiber mesh’s lightweight nature can be advantageous in reducing the overall weight of the structure. In contrast, wire mesh’s weight may be a considerably heavier but have a good load bearing capacity making it suitable for heavy-duty applications.

Applications and Use Cases

Fiber mesh and wire mesh are both suitable for various construction applications, including residential, commercial, and industrial projects. The choice between the two depends on project-specific requirements and budget constraints.

Conclusion

In the ongoing debate on “Is Fiber Mesh Better Than Wire Mesh“, there’s no one-size-fits-all answer. Your choice should be guided by the specific needs of your project, budget constraints, and aesthetic considerations. Both materials have their merits and limitations, so make your decision after careful evaluation.

FAQ (Frequently Asked Questions)

Wire mesh is highly effective in preventing the propagation of cracks in concrete, providing superior crack control compared to fiber mesh.

Wire mesh is often more cost-effective due to its efficient installation process and ability to prevent cracks, which can reduce material and repair costs.