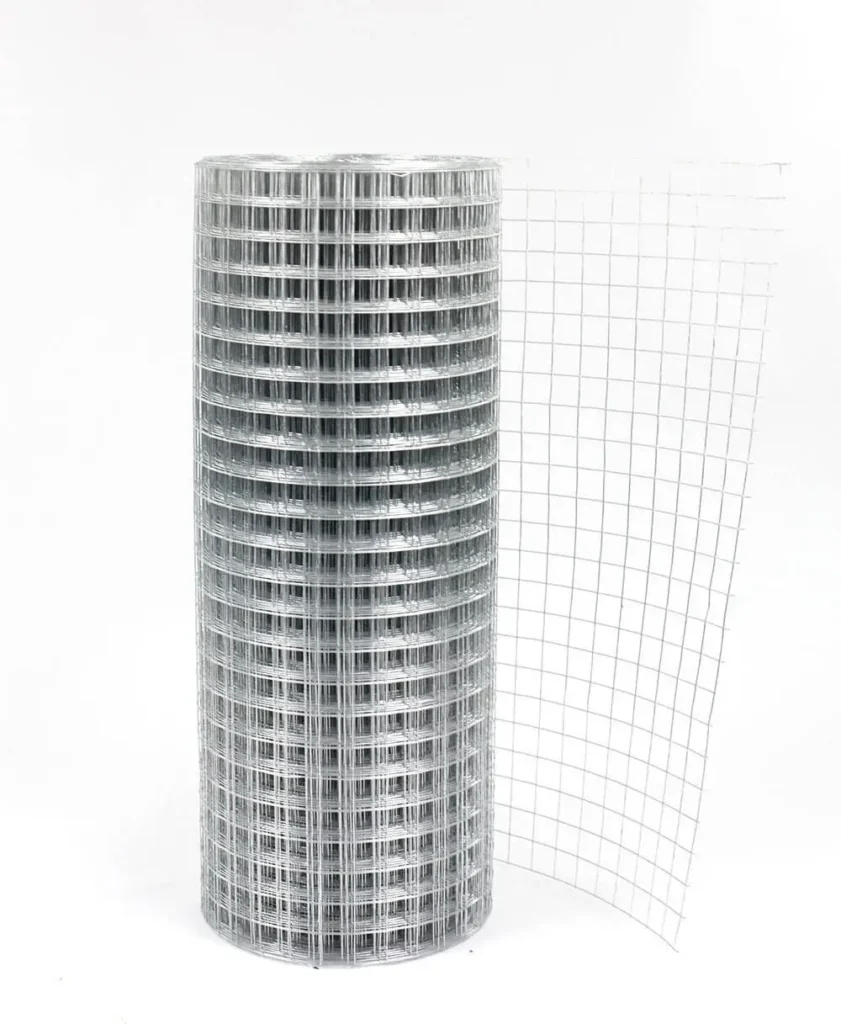

Welded wire mesh, also referred to as welded mesh or welded wire fabric, is grid-like framework formed by welding metal wires together. It possesses a wide array of special attributes that render it an excellent option for diverse uses. Ranging from strength and durability to flexibility and resistance to corrosion, different types of welded wire mesh encompasses a broad spectrum of qualities.

So, lets uncover the types of welded wire mesh, their properties, applications and more in this guide.

Understanding the types of Welded Wire Mesh:

Welded wire mesh exists in various types, each tailored to meet specific needs. The primary types of welded wire mesh include:

Electro Galvanized Welded Wire Mesh

Electro Galvanized Welded Wire Mesh is welded wire mesh, zinc coated through electro galvanization, this variant of welded wire mesh exhibits corrosion resistance, making it an ideal choice for outdoor usage where exposure to the external environment is a concern.

Hot Dipped Galvanized Welded Wire Mesh:

Hot Dipped Galvanized Welded Wire Mesh is one of the types of welded wire mesh with a thicker zinc coating late. The zinc coating is applied by hot dipping mild steel wire into molten zinc. The hot dipped welded wire mesh posess greater levels of corrosion resistance property due to the thick zinc coating.

PVC Coated Welded Wire Mesh:

In PVC Coated Welded Wire Mesh, the mild steel wire is hot dipped over which a layer of polyvinyl (PVC Coating) os added to enhance the corrosion resistance property. Ideal for applications in gardens, landscaping, and residential fencing.

Stainless Steel Welded Wire Mesh:

Crafted from high-quality stainless steel, the Stainless Steel Welded Wire Mesh offers exceptional resistance to corrosion, even in moist environments. It finds utility in construction for reinforcement, fencing, and more.

Properties of Different Types of welded wire mesh:

When selecting the appropriate welded wire mesh for your project, understanding its properties is paramount.

Strength:

Strength stands as a key attribute of welded wire mesh, thanks to its interconnected wires forming a grid-like structure that provides excellent structural support. This makes it ideal for high-tensile applications such as reinforcing concrete slabs or walls.

Durability:

Durability is another hallmark, stemming from the secure bonding of wires during the welding process. This renders welded wire mesh resistant to bending, twisting, and breaking, ensuring suitability for long-term outdoor use.

Flexibility

Flexibility is yet another advantage, facilitated by the grid-like structure allowing for easy bending and shaping to meet various project requirements.

Corrosion Resistance

Additionally, welded wire mesh offers superb corrosion resistance, often achieved through galvanization or protective coatings, making it suitable for humid or corrosive environments.

Applications of Types of welded wire mesh across Industries:

- Welded wire mesh finds utility across a multitude of industries owing to its versatility. In construction, it is commonly used with concrete to prevent cracks and reduce the overall weight of foundations, particularly in multi-story buildings.

- In landscaping, galvanized welded wire mesh aids in erosion control, soil stabilization, and retaining walls, contributing to stable and visually appealing landscape features.

- In agriculture, it serves in creating animal enclosures, fences, and cages, offering a secure barrier while ensuring proper ventilation and visibility.

- Even the art industry embraces welded wire mesh, utilizing PVC welded wire mesh for sculptural creations due to their flexibility and strength.

Conclusion

In summary, welded wire mesh stands out as a versatile material offering a multitude of properties, applications, and advantages. Its strength, durability, and adaptability render it suitable for diverse projects in construction, landscaping, agriculture, and the arts. Moreover, its cost-effectiveness, minimal maintenance requirements, and eco-friendly nature enhance its appeal.

By familiarizing yourself with the various types of welded wire mesh, understanding their properties, aligning with project needs, and adhering to proper installation and upkeep protocols, you can fully leverage the potential of welded wire mesh in your endeavors.